235 & 261 Cubic InchModifications/ConversionWords of caution there are differences between the Canadian and US manufactured 235 and 261 engines so be sure you know which one you have. Though many if not all parts maybe interchangeable beware. Also because many parts are interchange able between 216, 235, and 261 you may find that "1962 261 cubic inch Jobmaster" has the head of 1958 235 Thriftmaster head. I've seen a 235 with three different types of intake valves fitted and it ran fine. |

|

|

Though the original Chevrolet 216 engine is a strong and long lived engine, today's traffic and expectations that trucks can run up any hill without slowing down makes up grading the power for CMPs a reasonable conversion particularly for the larger trucks. I've driven my HUP BEAST with its original 216 engine since I got it in 1978. The engine on the HUP has NEVER been apart, I've never even dropped the pan on this engine. It still runs good and I really hate to mess with success. BEAUTY a 1942 C60S the engine has been disassembled and to be cleaned but not rebuilt when I restored the truck in 1990. At that time the only major engine work was having the crank turned because the rear main leaked oil so bad. I've been driving Beauty now for more 18 years years and the engine is getting a little tired with 17606.4 miles on it now it has already gone longer than the normal rebuild distance for trucks of the 1940s. The other issue was oil leakage 18 years is just longer than cork and paper gaskets were intended to last. While by today's standards this sounds like no mileage at all, it must be remembered that these engines spent much of there life running either wide open or at idle. A 216 engine puts out 85 hr power when new this is pulling an 11,000 lbs. truck (BEAUTYs weight with the radio box) works out something just over 15 horsepower per ton. (modern cars routinely have 100 HP per ton.) At full all up load for a 3 Ton CMP cargo truck 17,000+lbs. works out to just about 10 horesepower per ton. |

|

|

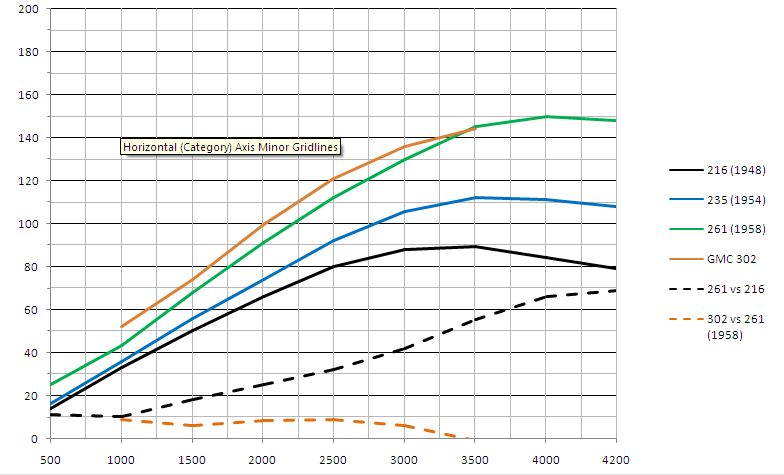

The Chevy Stovebolt as with the Ford V8 of this time period 1940-1950 became favorites of the post war Hot Rodders. This was in part due to the large number of surplus engines that were available cheap. So much experimenting in getting more power out these engines went on. The CMPers with a Chevy truck have another advantage the 216 Chevy engine is physically the same size and appearance as Chevy 6 cylinder engines from something like 1939 to 1962. This wide time spead lead to many improvements two of which are of particular interest as engine replacements the later version of the 235 Cubic Inch and the best of the transplants the 261 Cubic Inch truck engine. The 261 featured nearly 65 more horsepower and 1000 RPM more useable RPMs it also featured a full flow filter oil system which means all the oil goes through the oil filter all the time not just a percentage of the oil as with the earlier by pass filter engines. Another advantage is that the both (later) 235 and all the 261s are full pressure crank engines instead of the splash lubrication system of the 216. This change is very noticeable in the oil pressure you see with a 216 the book said any oil pressure showing meant things were OK. With the 235 and 261 they basically run with 20-40 PSI pressure all the time. One thing must be understood about the 216 is though a low pressure system it was pumping an incredible amount of oil around the engine. Running all three engines on the test stand with clear viewing panel installed the amount of oil being pumped is impressive. The graphs at left I found on the web an report to show the actual result of Dynomoniter test on a 1948 216 engine, 1954 235 and 1958 261 as well as a GMC 302. |

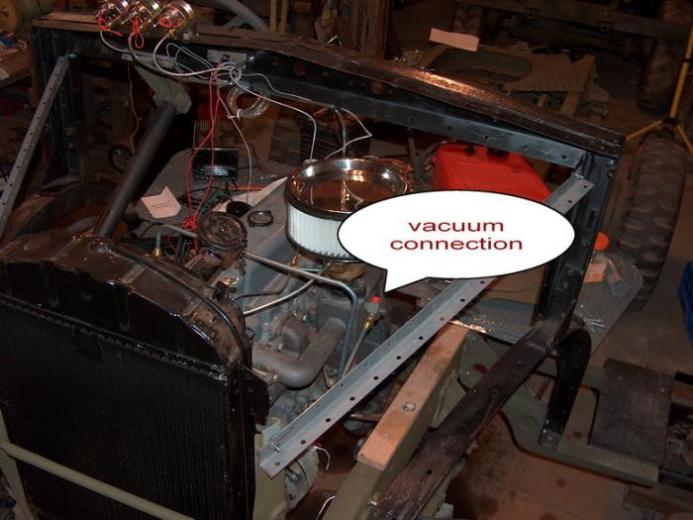

| One of the conversion/adaptation problems of putting a 235 or 261 engine in an earlier Chevy application is the placement of the Water Pump at right you will see the placement of the 261 and 235 water pump. There are also issues about the size of the pulley, if you use the standard 216 ('53 pulley that matches the adapter plate) the fan speed will be very excessive. At left you see the fix for this problem which is to use all the original CMP pulleys. What ever you do match pulley sizes as sets, particularly crank pulley to water pump/fan pulley. The combination below show the problems the left works OK as does the right. The pulley combination in the center DOES NOT it over speeds the water pump but it radically overspeeds the stock 6 bladed fan. The air stream is so strong going across the top of the engine that it starts sucking oil out of the oil filler cap. Plus I suspect that highway speed the fan is liable to fail loosing blades. | |

|

|

|

| In the 1960 235-261 Engine Manual. Page you will find some interesting information on the differences about the cam shafts used on the 235 and 261 and yes they will interchange. But be careful as the 261 cam has a higher lift and different valve timing and I understand that when used in combination with certain 235 heads of different years that the valves may not clear the top of the piston. | There are also some issues with hydralic valve lifters as to which engines they can be fitted to (see page page 8-11 of the 1960 Chevy Truck Manual ) as not all engines can use all hydralic or solid lifters. In some cases it appears that they may block the oil from gettting to the rocker arm assembley. |

|

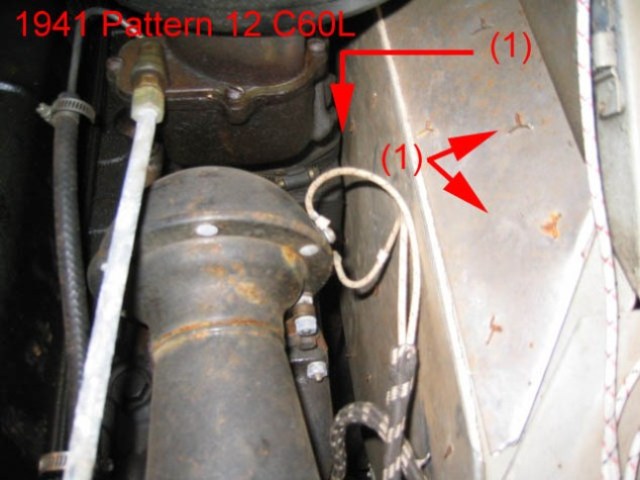

There is a concern with manifold clearence on Pattern 11 and 12 conversions to 235 or 261 engines. The problem is that normal vacum port comes out the side of the manifold just below the carberator. See picture at (right n) of Bob Carriere's Patter 11 C15 the picture shows the large vacuum connection. While the two pictures below show my Pattern 12

Picture (below) shows the lack of clearance on my Pattern 12 C60L. Now as to clearance between the side of the manifold and the engine side cover on the Pattern 12 there isn't any from the side of the engine where the intake and exhaust mate with the head to the inside of the insulation on the engine side cover is just over 6 inches the 235 intake manifold I have measures 5 ½ inches so it is tight. Below right, shows the brake booster vacuum connection. Below shows the very tight clearance to the side of the engine dog house. If you are wondering what I did for heat insulation, I did use asbestos board like the orginal BUT it is wrapped in aluminum the double arrow (1) is pointing to how I attached the insulation panels which orginally were held with staples, as a replacement I used mig welding wire which on the inside of the cab looks like the orginal staples and when twisted inside provide a very solid application method. |

|

|

|

|

One of the big problems with engine converstion is the throttle linkage on Pattern 11, 12, or 13 the only practical method is to fabricate a totally new linkage (if you have a good orginal 216 linkage tag it and save it). There are a couple of issues in routing the throttle linkage across the front of the block some are related to the water pump location and pulley size or combination of pulleys. The two pictures below show the stock 216 front throttle linkage note that linkage attaches to the thermostat housing .

|

The two photos at below show fabricating a new throttle cross shaft for the 261 engine with the proper 261 thermostat housing and with adapter that allows using a 216 water pump at the proper location which allows the retaining the orginal fan and fan shroud. (the pulley on the water pump has not been changed yet) When you are fabricating the new linkage don't rush to weld your lever arms, you will want to make sure that you get full throttle action without any of the links hitting things. I did mine as a tight fit on the shaft then finished fabricating all the linkages from the peddle foward to driverside lever arm, off side arm back to the block pivot point, and finially up to the carborator. All of this is done best with the engine installed in the truck but without the radiator in possition. As mentioned you want to have full throttle range while preserving spring over ride on the finial linkage up to the carborator so that the throttle stop on the carb is not trying to hold back your foot when you try to floor the throttle. Your foot would win the battle and brake or bend the carborator throttle stop. I fabricated all new linkages so that I could save the orginal shaft and linkage complete and installed them back on the trucks orginal 216 cubic inch engine which I've kept complete and in operational condition.

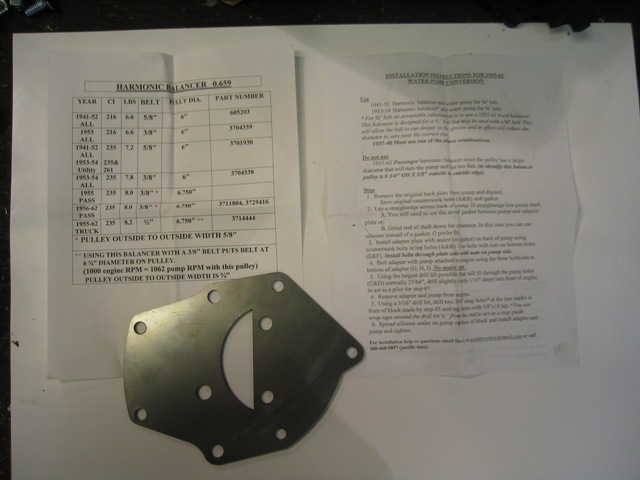

Below are a series of photos showing the waterpump adapter plate.This adapter plate allows the use of a 216 water pump on a 235 or 261 engine which keeps the orginal position of the fan which is important on a CMP. |

|

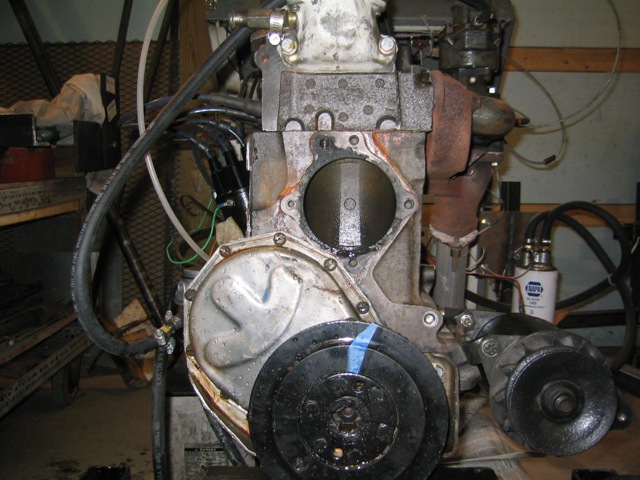

Picture below is of 261 engine with the standard water pump removed, picture at left shows the addapter plate installed. Instaling this plate requires drilling and tapping to new bolt holes in the block. Get this correct is obviously important, but care and taking your time are all it takes to get it correct.

|

|

|---|---|

|

|

|

The adapter plates I purchsed came from the supplier on e-bay, yes I purchase 2 plates one for my 261 engine and the other for 235 engine they came with good clear instructions. The discussion of pulley size is very important particularly with the 6 bladed CMP fan. (See the photos and discription near the top of this page) |

|

|

|

|

|

Return to 1960 235-261 Engine Manual. Page |

|

Return to Engine Test Page |

Return to Home Page |