| Go To HUP OVERHAUL

2011- Page 1 |

Go To

HUP OVERHAUL 2011- Page 2 |

| April

Work - Page 3 was centered around the Transmission, Spring

Shackles, Cleaning and Painting of the bottom of the body, Engine Testing

then disassembly. |

May

Work

- Page 4 included finding a replacement cylinder head, finding

and installing spring shackle bushings and pins. Cleaning and painting

the frame, |

| June

Work

- Page 5 painting and body work begins and trying to match

the original color of the HUP, brake work, reassembly of the axle assembly. |

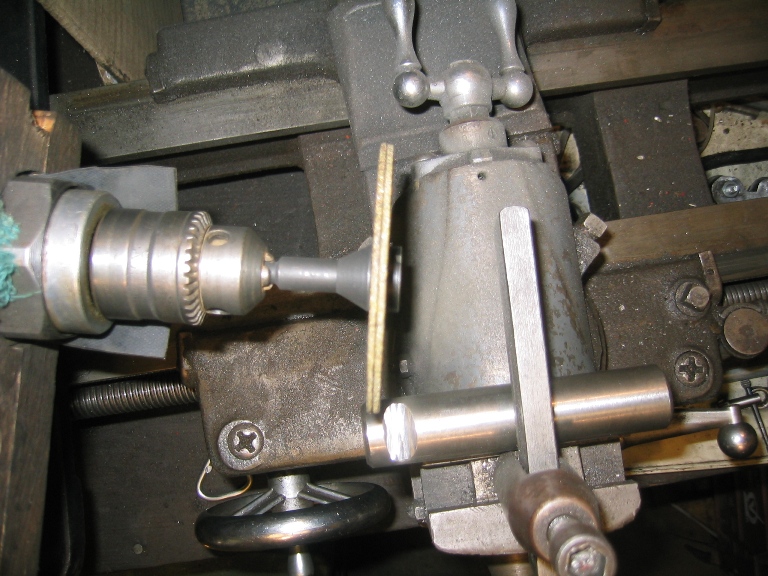

July

Work

- Page 6 handling painting and body how do you pick up and turn

a HUP body on its side by yourself. Machining the hardened steel spring

shackles. Pictures of the wooden blocks used as frame inserts at the attachment

locations. Brake line installation |

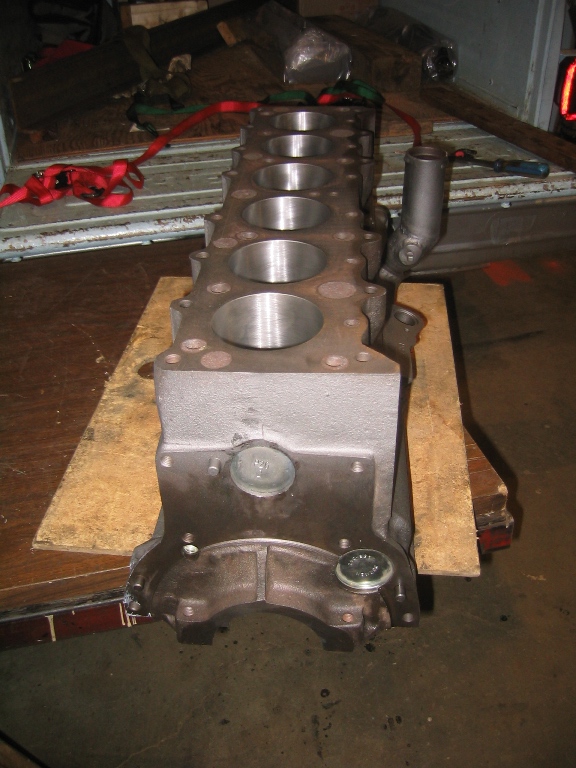

| August

& September Work

- Page 7 engine comes back from the machine shop almost ready

for reassembly before the problems start. Body lowered on to the body

for fitting and further body work, which included replacing some rusted

damaged areas. |

October

& November Work

- Page 8 body work continues, repairing the fatigue cracks in

the front door where the hinges attach, a common CMP problem, installation

of chassis parts like shocks. Problems with assembly of the engine but

in the end everything is fitted in place. |

| December

Work - Page 9 engine assembly completed and run in started on

the test stand. Hidden design surprises in the CMP adaptation of the Stovebolt

6. Work on the chassis nearing completion with only a little painting

and the installation of the wiring harness to be done. Body is ready to

be primed and painted. |

|

| BACK TO HOME PAGE |

| Go To HUP OVERHAUL

2011- Page 1 |

Go To

HUP OVERHAUL 2011- Page 2 |

| April

Work - Page 3 was centered around the Transmission, Spring

Shackles, Cleaning and Painting of the bottom of the body, Engine Testing

then disassembly. |

May

Work

- Page 4 included finding a replacement cylinder head, finding

and installing spring shackle bushings and pins. Cleaning and painting

the frame, |

| June

Work

- Page 5 painting and body work begins and trying to match

the original color of the HUP, brake work, reassembly of the axle assembly. |

July

Work

- Page 6 handling painting and body how do you pick up and turn

a HUP body on its side by yourself. Machining the hardened steel spring

shackles. Pictures of the wooden blocks used as frame inserts at the attachment

locations. Brake line installation |

| August

& September Work

- Page 7 engine comes back from the machine shop almost ready for

reassembly before the problems start. Body lowered on to the body for

fitting and further body work, which included replacing some rusted damaged

areas. |

October

& November Work

- Page 8 body work continues, repairing the fatigue cracks in

the front door where the hinges attach, a common CMP problem, installation

of chassis parts like shocks. Problems with assembly of the engine but

in the end everything is fitted in place. |

| December

Work - Page 9 engine assembly completed and run in started on

the test stand. Hidden design surprises in the CMP adaptation of the Stovebolt

6. Work on the chassis nearing completion with only a little painting

and the installation of the wiring harness to be done. Body is ready to

be primed and painted. |

|

| BACK TO HOME PAGE |